Syrup Bottle Filling Line

Product Description:

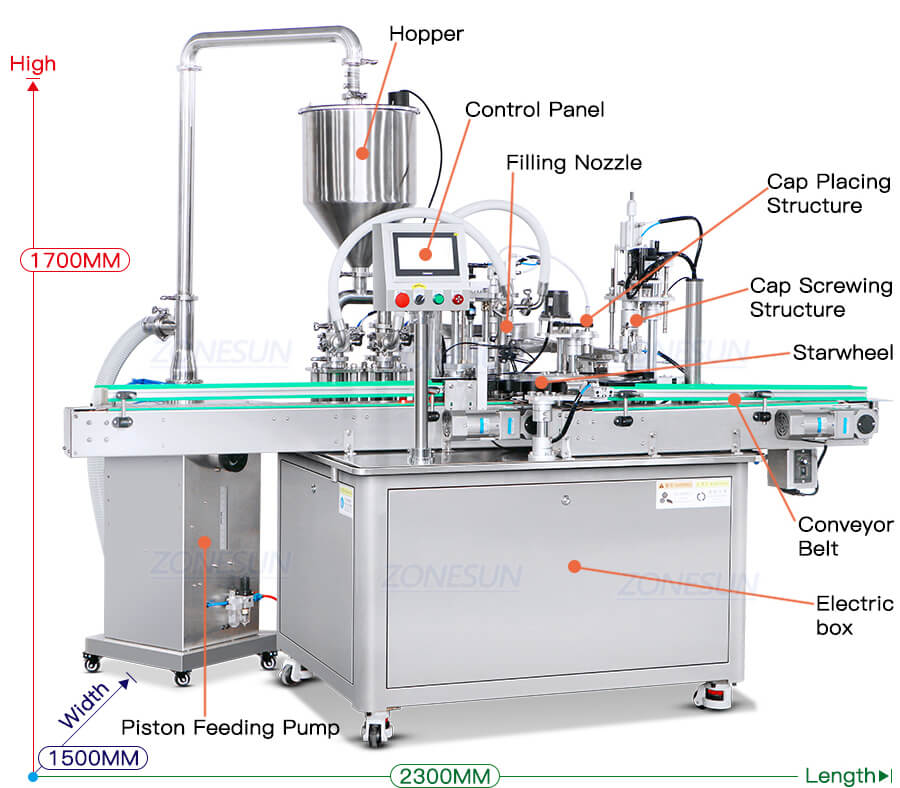

This packaging system is consist of monoblock filling capping machine which is controlled by cam working system and a round bottle labeler. It can realize the filling, capping and labeling work at the same time for the small bottles with screw-on caps like syrup, essential oil, eyedrops, energy drinks.

Product Parameters:

Machine Model | ZS-AFC34 |

Power | About 4.2 KW (220V 50Hz) |

Cover Size | Customized |

Bottle Size | Customized |

Filling Capacity | 200-300 ml (based on syrup) |

Filling Pump | Double-head servo piston filling |

Filling Accuracy | About ±2% |

Production Efficiency | 30BPM(based on filling volume and filling material) |

Working Air Pressure | 0.6-0.8mpa |

Machine Size | About 2300*1500*1700 (mm) |

Machine Weight | About 800kg |

Machine Model | ZS-TB822 |

Voltage | 220V/50HZ 110V/60HZ |

Power | 570W |

Labeling Accuracy | ±1mm |

Labeling Speed | 25-45 bottles/min |

Applicable Product Size | φ15-120mm H:25-300mm |

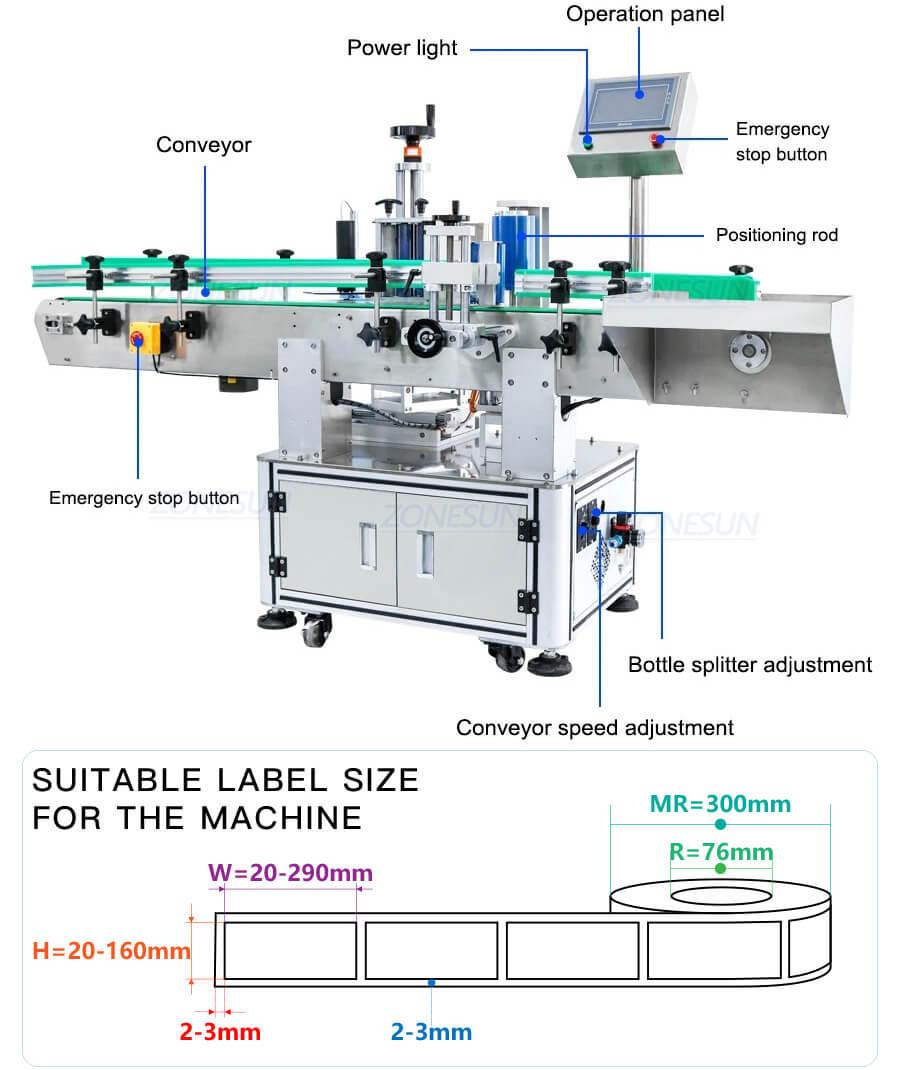

Label Size | 20-290mm(W)*20-160mm(H) |

Label Roll ID | φ76mm |

Label Roll OD | φ300mm |

Machine Size | About 2150*1100*1440mm(L*W*H) |

Machine Weight | About 222kg |

Product Details:

Touch screen interfaces allow for easy customization of controls and settings, making it simple to adjust parameters for different products and production requirements. This flexibility enhances the versatility of the filling and capping machine.

Equipped with pneumatic anti-dripping filling nozzles, these are designed to prevent dripping of product after filling. This is particularly important for liquids with high viscosity or foaming characteristics, as dripping can lead to product waste, messy production environments, and potential contamination of packaging.

Using air nozzle to pass allows for rapid movement of the caps, improves working efficiency. Servo motor control the capping work, this machine has higher capping accuracy.

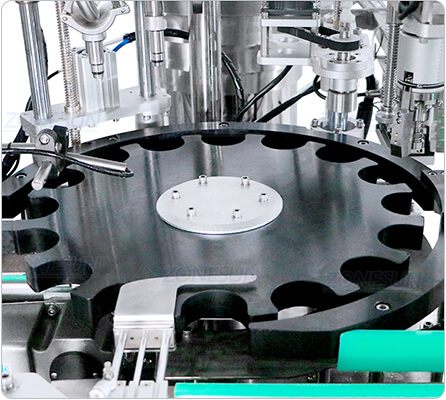

Starwheels provide precise alignment and positioning of containers and caps as they move through the filling and capping process. This ensures that each container is correctly oriented and secured before filling or capping, minimizing the risk of misalignment or errors.

Designed for round bottle labeling, this labeler machine is suitable for single side, double sides and wrap-around labeling. This kind of labeling method can ensure there is no bubbles under stickers.

Equipped with bottle turntable machine, they can handle a high volume of bottles quickly and consistently, reducing manual labor and increasing throughput.