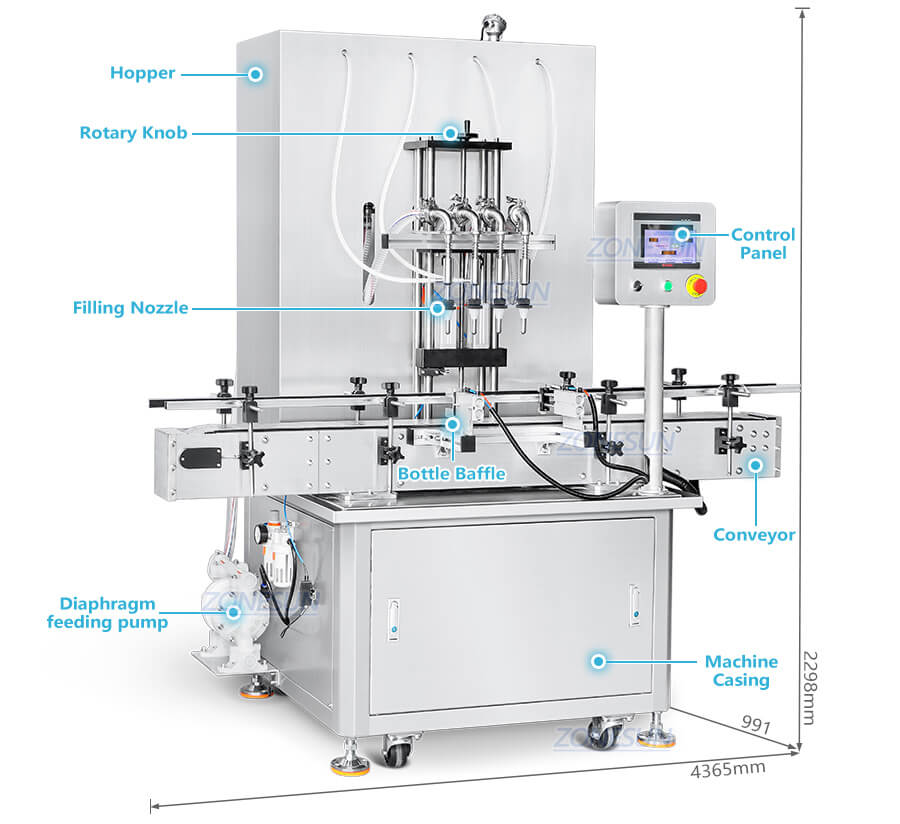

Liquid Overflow Filling Machine With Feeding Pump

Product Description:

This filling machine is designed to accurately fill bottles to a predetermined level, typically by filling them slightly above the intended fill line and then allowing the excess liquid to overflow. This ensures that each bottle contains the exact same volume of liquid, resulting in consistent filling levels across all bottles. It is often used in distilleries and bottling plants to efficiently and accurately fill bottles with spirits such as whiskey, vodka, rum, and other alcoholic beverages.

Product Parameters:

Machine Model | ZS-VTGZ100 |

Machine Voltage | 110/220V 50-60HZ 250W |

Quantity of Filling Nozzle | 4 |

Working Capacity | About 15-20BPM(based on 500ml liquid) |

Air Pressure | 0.4-0.6MPA |

Suitable Filling Volume | 50-5000ml |

Suitable Bottle Height | 120-280mm |

Suitable Bottle Opening Mouth | 20-35mm |

Machine Size | About1900*1100*2050mm |

Product Details:

PLC control panel provides precise control over the filling process, allowing for accurate adjustment of fill levels, flow rates, and timing. This ensures consistent filling levels across all bottles, contributing to product quality.

Filling nozzles are engineered to allow the excess liquid to flow out of the bottle neck and back into the reservoir, ensuring that each bottle is filled to the desired level without spillage or underfilling. Multi filling heads can be customized as needed.

The electric eye is often integrated into automated filling lines, allowing for seamless operation without the need for manual intervention. This streamlines the production process and reduces the reliance on human operators.

Liquid level sensors provide real-time feedback on the fill level during the filling process, allowing for immediate filling material supplying adjustments. This ensures that any issues can be addressed promptly, minimizing product waste and rework.

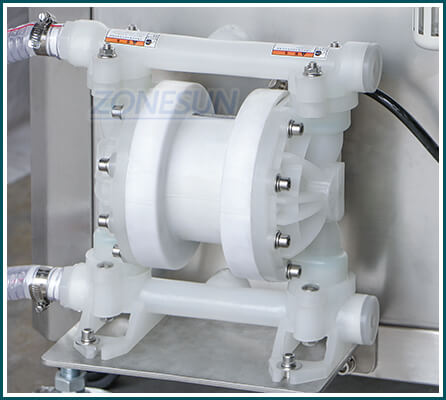

Equipped with diaphragm feeding pump, it can ensure filling material can be supplied in time and filling work can be processed smoothly, this greatly improves working efficiency.

Chain conveyor belts are capable of handling high volumes of bottles efficiently, making them suitable for high-speed filling lines. They can transport bottles continuously and consistently, maximizing production throughput.