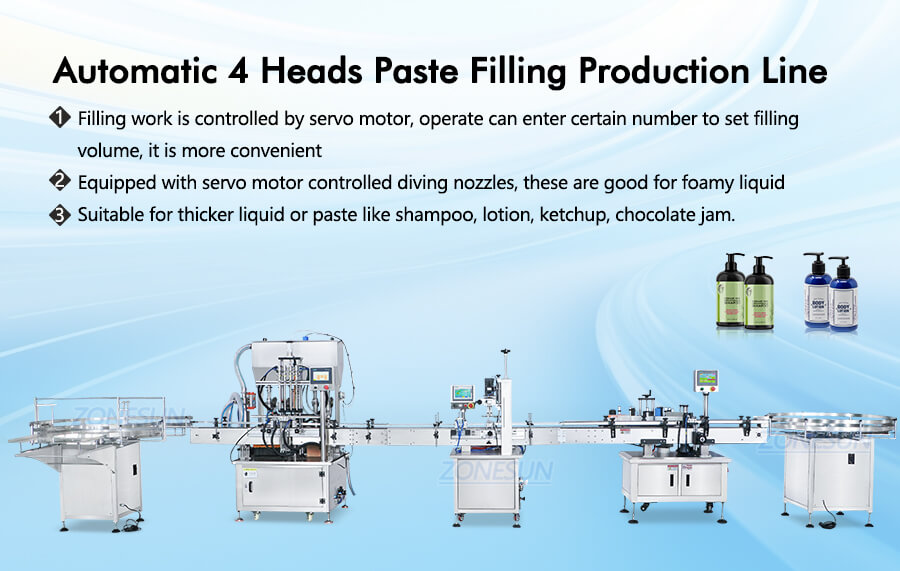

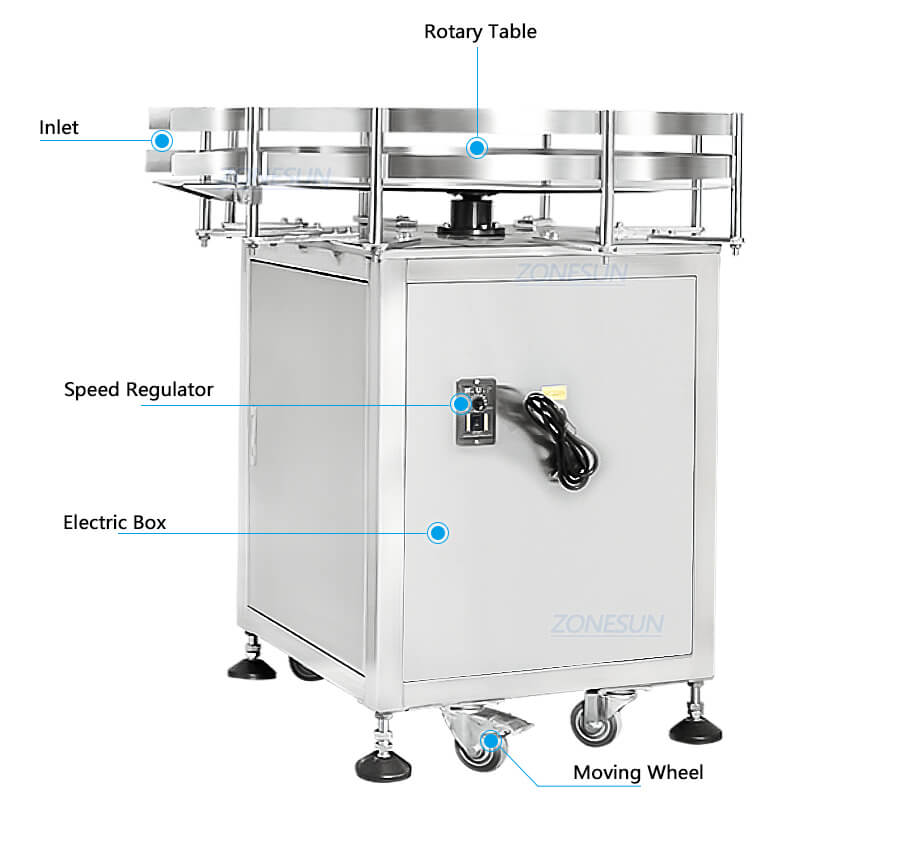

Automatic 4 Heads Paste Filling Production Line

Product Description:

This piston pump paste filling line incorporates filling, capping, labeling machines, and bottle sorting system, ensuring accurate filling, customizable configuration, and reliable operation. Filling work is controlled by servo motor, advanced and precise control systems optimize performance, making it suitable for diverse production needs while complying with food safety standards. It is suitable for packaging shampoo, body gel, ketchup, chocolate jam, hand wash etc.

| Model | ZS-LP800S | ZS-LP1000S |

| Turntable Diameter | 800mm | 100mm |

| Suitable Bottle Diameter | 20-100mm | |

| Suitable Bottle height | 30-320mm | |

| Working Speed | 40-60 bottles/min(depends on bottle size) | |

Power Supply | 220V/110V 50-60Hz 200W | |

| Package Size | About 1150*1000*1320mm | About 1350*1315*1235mm |

Net Weight/Gross Weight | About 82kg/120kg | About 135kg/180kg |

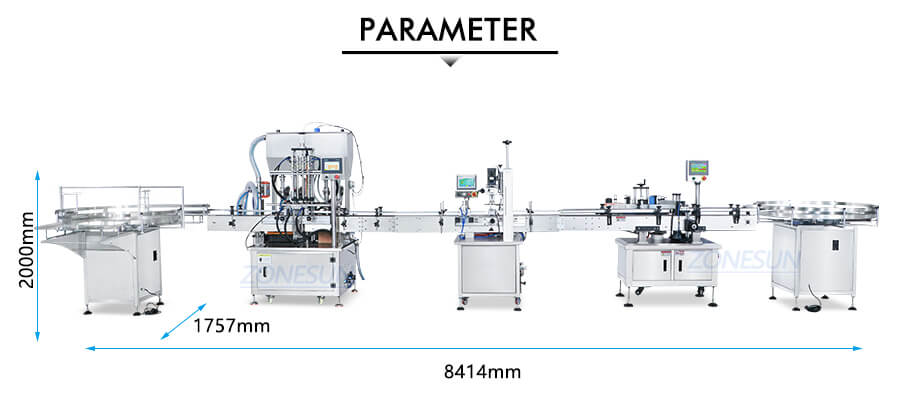

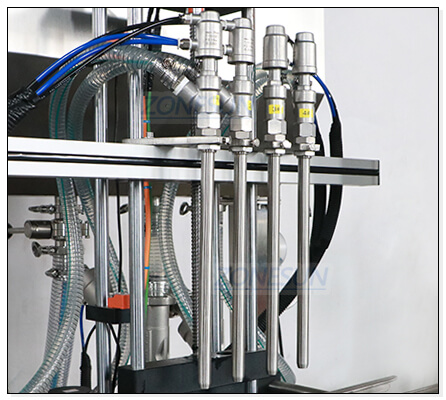

| Machine Model | ZS-YT4T-4PX |

| Voltage | 110/220V 50-60HZ 1KW |

| Filling Range | 10-180ml/30-500ml/100-1000ml |

| Working Speed | About 30-50bottles/min |

| Filling Pump | Piston pump |

| Air Pressure | 0.6-0.8MPa |

| Filling Accuracy | ±1% |

| Filling Nozzle | servo motor controlled diving nozzle (quantity can be customized) |

| Machine Size | About 2000*800*1800mm |

| Machine Weight | About 200kg |

| Packaging Size | About 2070*960*2010mm(100-1000ml) |

| Packaging Weight | About 392kg(100-1000ml) |

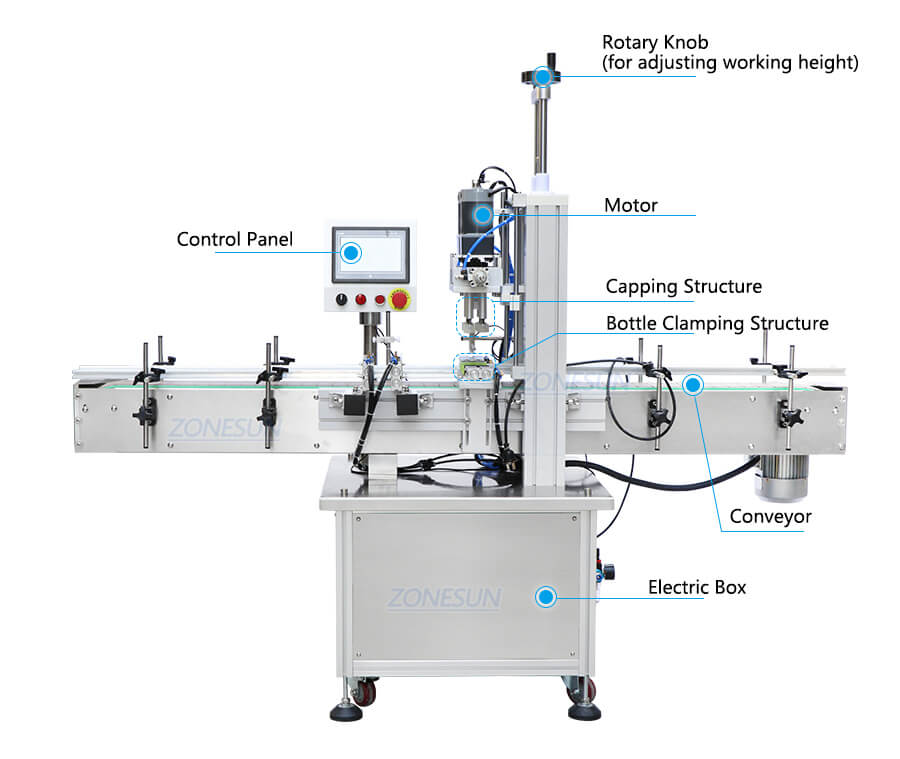

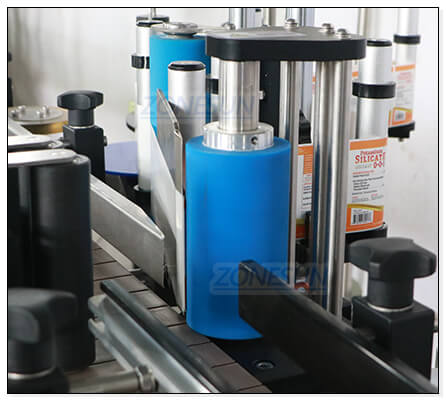

Machine Model | ZS-XG16 |

Working Voltage | AC220V/110V 50-60HZ |

Bottle Height | 30-300mm |

Cap Diameter | 18-70mm |

Bottle Diameter | 20-160mm |

Working Speed | 20-60 bottles / minute (depending on bottle and cap size and shape) |

Working Pressure | 0.4-0.6MPa |

Machine Size | About 1930*740*1600mm |

Packing Size | About 2000*820*1760mm |

Machine Weight | About 150kg |

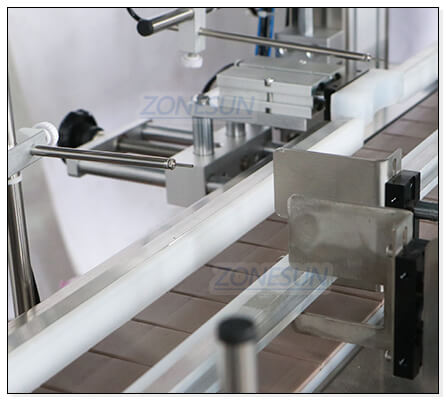

Model | ZS-TB260R Labeling Machine |

Power Supply | AC220V 50Hz/60Hz 1000W |

Labeling Capacity(bottles/min) | 25-50 bottles/min(depends on bottle size) |

Labeling Accuracy(mm) | ±1.0mm |

Suitable Bottle Diameter | Φ12-100mm |

Label Size(mm) | (L)20-300mm (H)15-150mm |

Roll Inside Diameter(mm) | Φ76mm |

Roll Outside Diameter(mm) | Φ350mm |

Conveyor Size | 112*2000mm(W) |

Machine Size | About (L)2000*(W)820*(H)1380(mm) |

Machine Weight | About 180kg |

Packing Size | About (L)2100*(W)890*(H)1520(mm) |

Package Weight | About 250kg |

| Machine Model | ZS-SP800S |

| Bottle Specifications | Square bottle/round bottle |

| Conveying Speed | 0-20 revolutions per minute(adjustable) |

| Voltage | 220V 50Hz (110V can be customized) |

| Power Supply | 200W |

| Turntable Diameter | 800 mm Available |

| Dimensions | About 550*550*990mm |

| Package Size | About 1050*1000*1130mm |

Net Weight/Gross Weight | About 93kg/120kg |

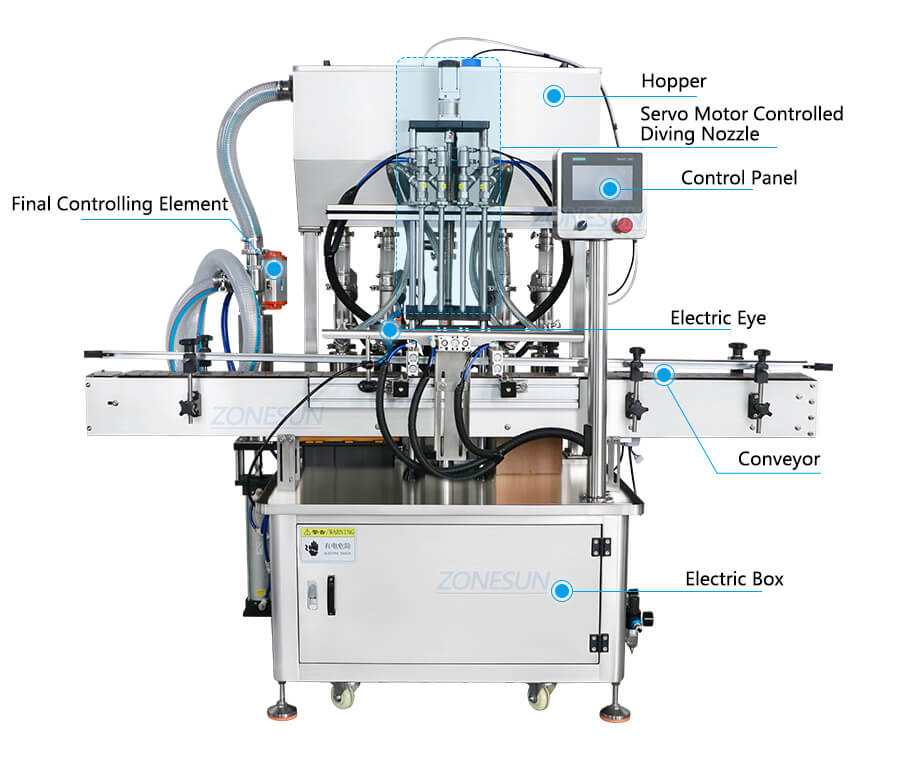

Product Details:

All machines are equipped with touch screen control panel, this can incorporate data logging and analysis features, allowing operators to track process parameters, performance metrics, and trends over time for optimization and troubleshooting.

Designed for thick paste or the filling material with particle, the final controlling element helps optimize the efficiency of the piston feeding pump and the overall process. This can improved production throughput.

Servo motors provide smooth and jerk-free motion, resulting in gentle handling of containers during the filling process. This minimizes the risk of product spillage or splashing,particularly for foamy liquid.

Capping work is controlled by four rubber wheels, this kind of capping structure is suitable for screw-on caps, the position of four rubbers can be adjusted according to cap size and shape.

The electric eye is used for sending signal to the system to control the automated work when it detects passing by objects.The position of electric eye can be adjusted according to operation need.

Designed for sticking labels on round bottles, it is suitable for single side, double sides and wrap-around labeling,it widens application range.

Connect with bottle turntable machine to make production be in order, make production be in order, the size of turntable machine can be customized as production need.