4 Heads Corrosive Liquid Filling Line

Product Description:

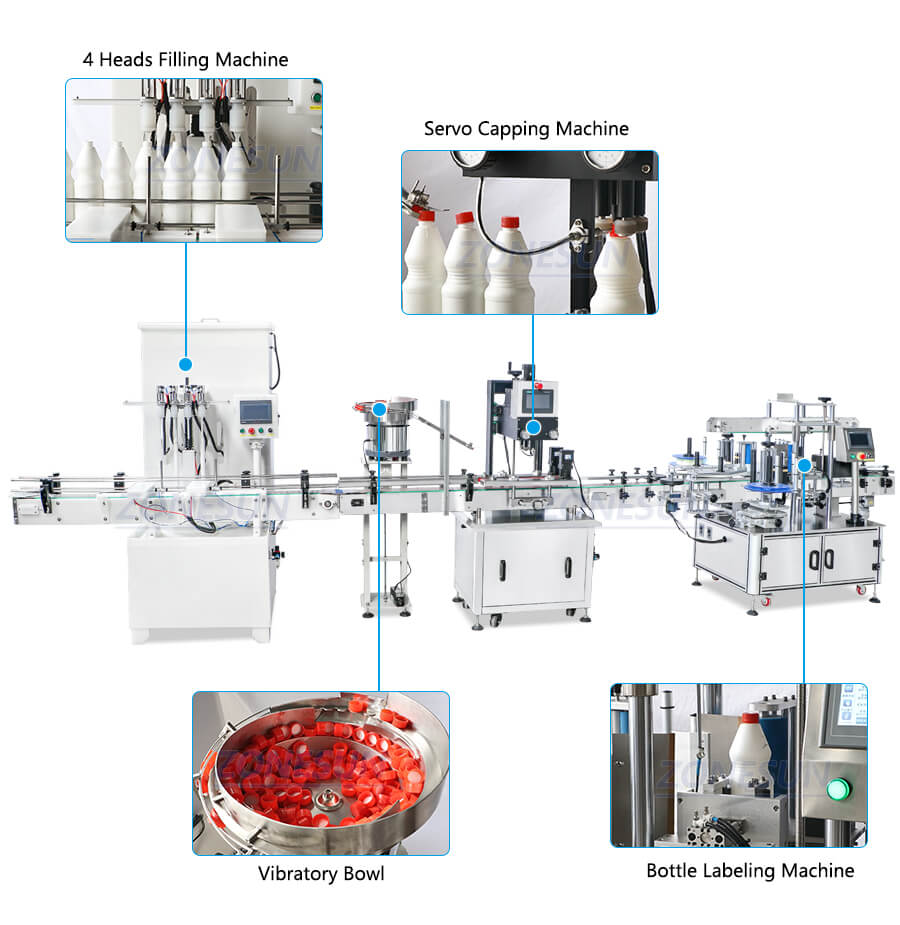

This packaging system is tailored for corrosive liquids like bleach and chemicals. It includes a corrosive liquid filling machine, a servo motor capping machine, and a bottle labeling machine. This full automation will significantly enhance your production efficiency.

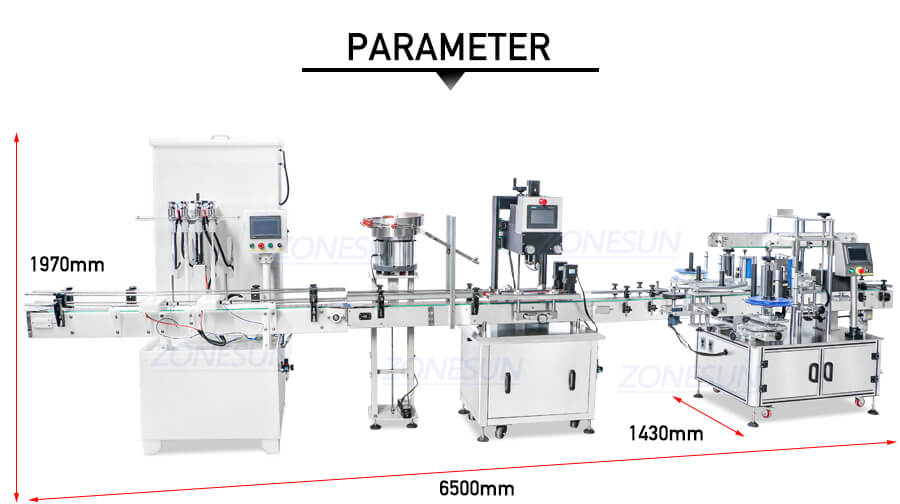

Product Parameters:

Machine Model | ZS-YTCR4A |

Voltage | 110/220V 50-60HZ 550W |

Air Pressure | 0.4-0.7MPa |

Suitable Bottle Diameter | φ60mm–φ120mm |

Suitable Bottle Height | 60mm–300mm |

Hopper Size | About 90L |

Filling Range | 100ml–3000ml |

Filling Speed | 200-2500 BPH (based on filling volume) |

Machine Dimension | About 2000mm*1300mm*1900mm |

Machine Weight | About 200kg |

Machine Model | ZS-XG440S |

Voltage | 110/220V 50-60HZ |

Machine Power | About 2.8KW |

Suitable Bottle Size | H=50-300mm φ=30-120mm |

Suitable Cap Size | φ=20-60mm |

Working Speed | About 30-100 bottles/min |

Machine Size | About 2000*750*1650mm |

Machine Weight | About 300kg |

Package Size | About 2070*830*1730mm |

Package Weight | About 321kg |

Machine Model | ZS-TB300Z |

Machine Power | 110/220V 2500W |

Working Speed | 30-150 bottles/min(based on bottle size) |

Labeling Accuracy | ±1mm |

Suitable Labeling Object | 30-300mm(L)*30-100mm(W)*50-350mm(H) |

Suitable Label Size | 15-300mm(L)*15-150mm(W) |

Label Roll OD | Φ280mm |

Label Roll ID | Φ76mm |

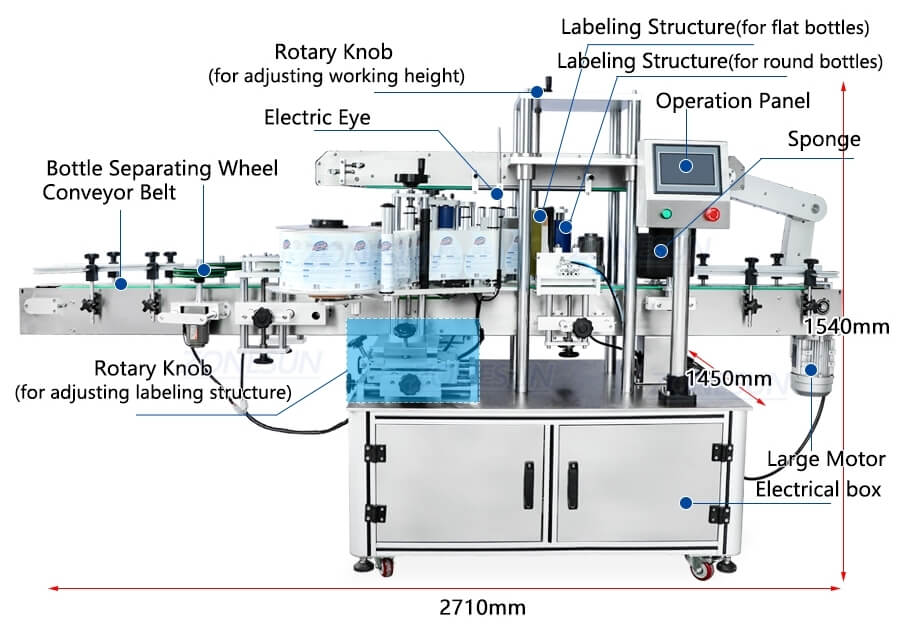

Machine Size | About 2710*1450*1540mm(L*W*H) |

Package Size | About 1900*970*1690mm |

Product Details:

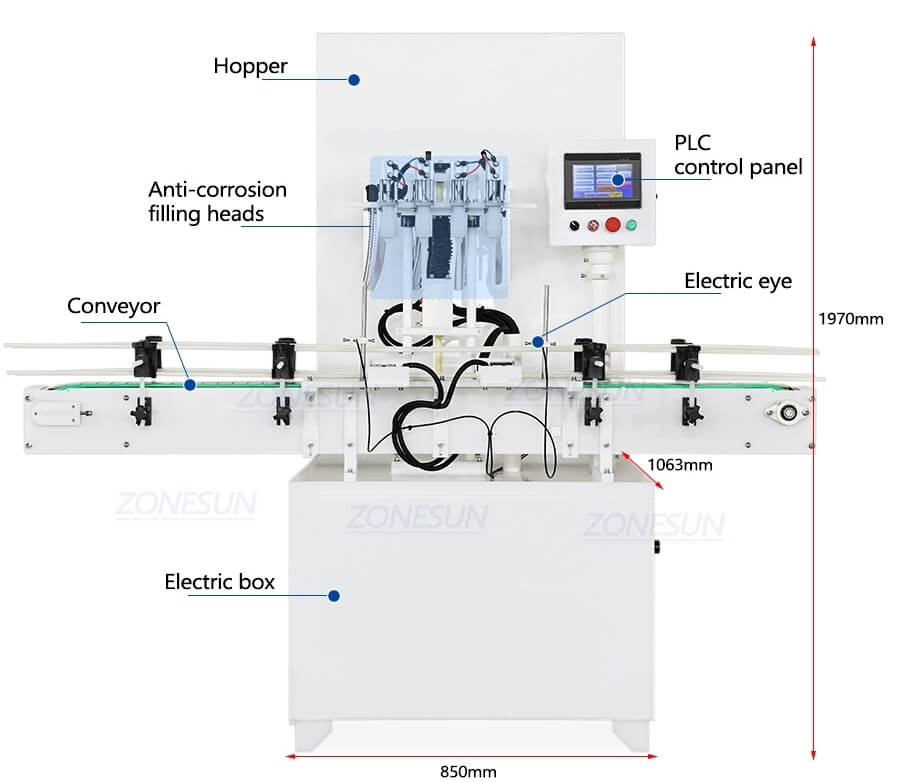

The touch screen control panel provides real-time monitoring of the machine’s performance and production status, streamlining the production process. We can customize different operation languages to suit your production needs.

We can customize the quantity of filling nozzles based on your production requirements. Our anti-corrosion nozzles ensure drip-free filling and enhance accuracy.

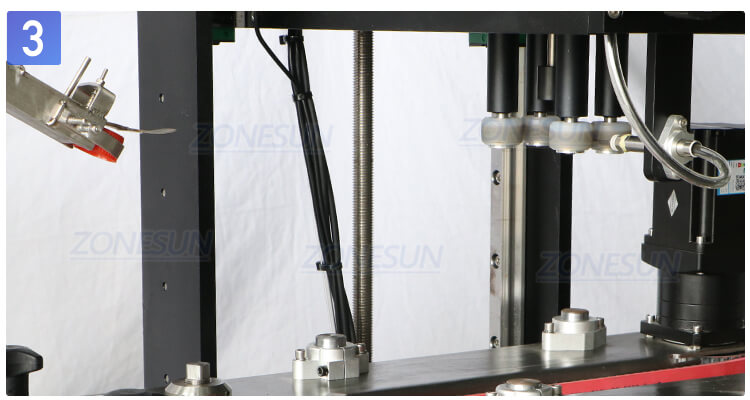

The capping process is driven by a servo motor, allowing for more precise control of the capping torque, ensuring efficient capping. The capping structure is comprised of four rubber wheels, adaptable to various bottle sizes and shapes.

Vibratory bowl sorters can efficiently handle a large volume of caps at high speeds, ensuring a continuous supply to subsequent capping processes, thereby enhancing overall production line efficiency.

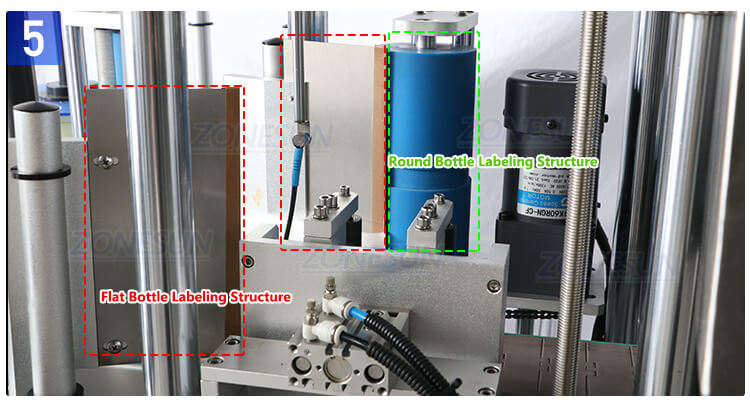

This dual-use labeling machine is ideal for both flat and round bottles. Each labeling head can be adjusted independently, allowing for optimal labeling of various products. We can customize the label roller to match the bottle shape, ensuring maximum accuracy.

The chain conveyor can be tailored to your specific production needs, ensuring it has a custom length and width. It also boasts a larger weight capacity, allowing for stable and smooth transportation of finished products.